There are a number of different bolt types and markings found on the Reichsbahn eagles. This page will go through the various aspects of the bolts and attachments in more detail:

There are a number of different bolt types and markings found on the Reichsbahn eagles. This page will go through the various aspects of the bolts and attachments in more detail:

- Bolts

- Bolt stamping

- Bolt locations

- Head stamping

- Swastika stamping

- Filing marks

- Lines on body

- “Original” Marking

- Mold leakage

- Uneven threading

- Imperfections

The example above shows the side of a train where the eagle was attached – the bolt locations are still visible.

Bolts

The reverse side of the Reichsbahn eagles contain any makers marks as well as bolts to attach the eagles to the trains. The number and location of the bolts varies by the maker. Many of the eagles in collections today have the bolts still intact whereas many others have the bolts cut or broken as they were forcibly removed from the trains. Some collectors items also still have the original washers and nuts used to attach them to the trains. Note the mounting for Reichsbahn eagles varies significantly from the mounts used on Reichspost eagles.

The Reichsbahn-Ausbesserungswerk (RAW – railway service station) or the Bahnbetriebswerk (DRB repair shop) were responsible for cutting the threads on the fastening bolts and positioning the eagles on the vehicles. They were rarely painted on the front, however many were painted on the reverse for protection.

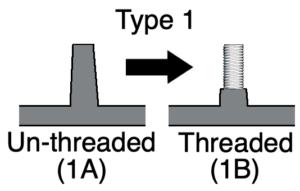

A number of eagles have “unthreaded” bolts. The most common of these is the “PS 24” eagles held in various collections. Additionally there are examples of other manufacturers with unthreaded bolts – “B”, “RMB”, “GJ/JG”, “ERNO”, “MF” and an unknown maker. These were never installed on trains and there are stories that a box of incomplete eagles was found at the end of the war in a factory or train station. I have also heard from a veteran that he found one amongst the rubble on the street after an allied bombing raid. The pictures below show some threaded and unthreaded bolts for comparison. The cones on these unthreaded eagles were dual purpose. First they provided “legs” to remove the eagle from the mold after it cooled. And secondly, when trimmed they provided the structures which were machined to create the fastening studs.

The bolt types have 5 variations (Types 1 to 5):

|

1A – Unthreaded are conical in shape, and when threaded the heights of the threads vary (depending on need)

1B – These have been machined to support a thread for attachment with nuts. Most eagles were attached using these threaded solid studs (Gewindezapfen) and were attached to either the cabin or engine. Most makers have unthreaded versions (potentially in addition to other types also). |

|

These are unthreaded and are smaller in height than Type 1 unthreaded (1A). They are also not conical.

Makers include: GJ/JG, PS, APAG , J&Z, GJ/JG, PF, B, RMB, ERNO, MF and an unknown maker |

|

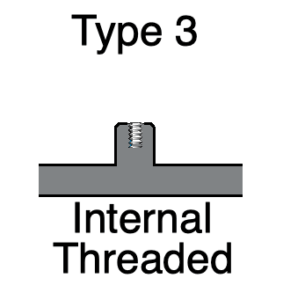

These are similar to the Type 2 but have an internal (inner) thread in the bolt to allow a screw to be inserted. Official drawings indicate that this inner threading method was done in the period for some makers.

Note: Studs with inner threading – It is common that collectors often create the inner threading to assist in mounting eagles with cut or broken threads. There are no period examples with both inner and external threading. Makers include: WEHAG, J&Z, APAG, ERNO, V, B, GJ/JG, ERNO, MF |

|

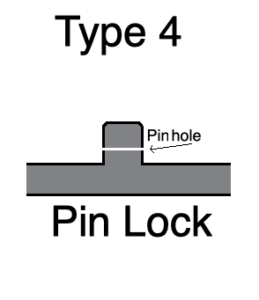

These examples have a hole through the unthreaded bolt (a Type 2 bolt) to allow a locking pin to be inserted to hold the eagle in place. These can often be seen on the examples where the bolt has been broken. |

|

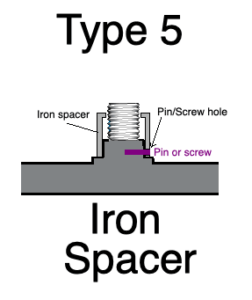

There is at least one example where the eagle was fastened by a 6.0mm screw with a 20.0mm spacer screwed to the cabin or engine. A pin was also used for securing the eagle to the screw bolt. This type of attachment is very rare and only one example is known.

Makers include: |

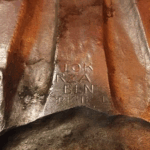

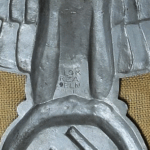

Bolt stamping

A number of the bolts on the reverse of the eagles also contains stamping with letters and numbers. These codes generally take the format of a larger cursive letter E – with an additional letter in the top of the E and a number if the bottom of the E. It is not known what these markings mean however it has been suggested they refer to the strength of the material. The numbers observed vary wildly and there is no correlation with any aluminium alloy modulus (engineering constant used to calculate material strength). It is also unlikely the markings refer to strength as the eagles aren’t critical structural components. Additionally strength values would be constant since the alloy composition is the same. The more likely scenario is that these markings are made as part of some sort of quality check process.

These have only been found on HE (finished HE’s) and PS (PS LOK’s, unfinished PS LOK’s, Unfinished PS Ellok’s) eagles. Some stamps are legible, some are illegible, some are complete and some are incomplete. There seems to be little concern about the stamp being perfectly applied. These have been applied to both threaded and unthreaded (unfinished) eagles.

The “V” eagle (last image) appears to have a “6” stamped on the top of the bolt.

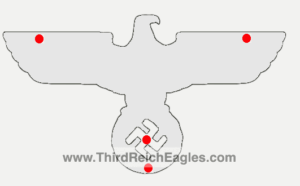

Bolt locations:

The following bolt location combinations exist:

- 3 Bolts Type 1 – One bolt on each wing and one under the swastika

- 3 Bolts type 2 – One bolt on each wing and one where the swastika joins the eagles body.(For front facing eagles)

- 4 Bolts Type 1 – One bolt on each wing (close to centre), one on the body under the head and one in the middle of the swastika

- 4 Bolts Type 2 – One bolt on each wing, one on the bottom of the swastika and one in the middle of the swastika

- 5 Bolts Type 1 – One bolt on each wing, one on each side of the swastika and one in the bottom of the swastika

Head stamping

Additionally, the above bolt stamping markings have also been found on some eagles heads (E.g. PS, HE) (known as Kennzeichnungsmerkmal) as shown below. Similar to the bolt stamping detailed above there is a cursive letter and number. Refer above for more details.

Swastika Stamping

There are examples of stamp marking on the swastika similar to the head and bolt stamping. The below examples shows what appears to be a M and a 45 inside a larger cursive E.

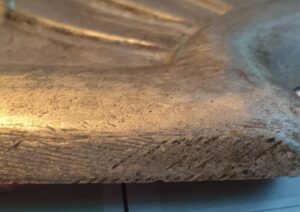

Filing marks

The eagles had any burr removed (Wagschleif-Verfahren) at the same location as the molding and before being delivered to the various depots. These depots were known as Reichsbahn–Ausbesserungswerk (RAW) or Bahnbetriebswerke (Bw) and were where the eagles were positioned on the engine or car. The stud/post threading always took place at the RAW or Bw. The grinding marks on the wings or other areas of the eagles can vary in depth and quality as they depended on the quality of the grinder and the expertise of the user.

Lines on body

A number of eagles (“PS”, “APAG”, “V”) can have a variation on the eagle front that results in a vertical line streaking between the legs of the eagle. Refer to the images below.

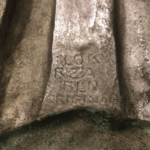

“Original” Marking:

A number of eagles (approx 3 known to have survived) have the “original” stamping on the back of the eagle above the swastika. These eagles were believed to have been produced by one or more development companies (“Entwickelungsfirma”) that took the lead in development on orders of the RZA. These are thought to be prototypes or early versions for review and approval prior to mass production. Very few examples have survived.

The RZA (Reichsbahn-Zentralämter) was the Reichsbahn Central Office responsible for technological development, standards, designs, specifications, requirements and procurement of rail vehicles and associated infrastructure. The RZA would prepare preliminary designs for industry and firms would submit detailed proposals.

Of the examples seen the makers are:

- J&Z (2 examples) – It is possible J&Z were a “Entwickelungsfirma” and included their makers mark OR potentially they took the prototype too literally and included the “ORIGINAL” markings on a few initial models by mistake.

- No maker (1 example) – As this has no makers mark it may have been provided to multiple makers as a prototype or produced by a “Entwickelungsfirma” to be more generic. It is 27″

Photos:

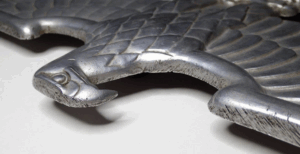

Mold leakage:

A number of eagles have areas that show leakage of Aluminium used in the mold. This is a normal aspect of the molding process. This leakage is generally around the mounting bolts and is more prevalent in the unthreaded models (possibly due to some cleanup as part of the threading process). Contrary to popular belief many German Third Reich items include imperfections, pitting or inaccuracies in their manufacture. The leakage on its own is not an indication of a reproduction (although reproductions may have this also) and is found on many examples to varying degrees. As part of the threading and cleanup process much of this leakage is often removed, hence why it is more prevalent on the unthreaded versions.

Examples:

Uneven bolt threading:

This PS LOK 600 example shows how sometimes the threading of the bolts can be unevenly applied. You can see where the machinist didn’t center the eagle properly in the jig. You will note that all the studs are equally shifted to the left….far off to the left. German manufacturing wasn’t always perfect. Also, you can see that as they had machined so far to the left, there was extra material left on the stud cone. These burrs have also been chipped off by the machinist after the threading. Hence the jagged edges on all of the right side of the stud bases.

Imperfections:

Many eagles show other signs of imperfections, particularly on the backs. This includes non-smooth areas and small lumps of aluminium. Additionally the makers mark can be less than perfect with Aluminum covering aspects. When validating eagles this should be taken into account and is not an indiction in itself of a reproduction. The highest quality eagle backs generally come from the J&Z, “V” and RMB makers. It is not uncommon for most backs of eagles to be rough and have many imperfections.